Plastics are an integral part of modern life, with numerous applications across various industries. From packaging materials to automotive components, the versatility of plastics is unparalleled. Among the many types of plastic, each serves a unique purpose, contributing to the functionality and efficiency of products we use daily.

As we explore the diverse categories of plastics, their properties and uses reveal fascinating insights into how they shape our world. Get ready to uncover the remarkable characteristics that distinguish each type and their impact on our environment and economy.

The different types of plastic is crucial in today’s world, where plastic pollution poses significant environmental challenges. Each type of plastic has unique properties, applications, and recycling capabilities, influencing how they are used and disposed of.

By recognizing these differences, consumers can make informed choices about plastic products and their impact on health and the environment. Below is a detailed overview of the various types of plastics, their characteristics, and applications.

Plastics can be classified into two primary categories:

By understanding these types of plastics, individuals can better navigate their choices regarding usage, recycling options, and environmental impacts associated with plastic products.

Now, let’s look at some common types of plastic you encounter daily. Polyethylene (PE) is used in everything from grocery bags to children’s toys. Polypropylene (PP) is known for its durability and is found in items like reusable containers.

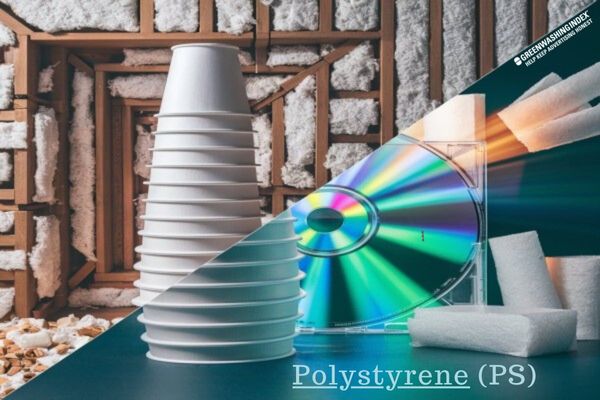

Polyvinyl Chloride (PVC) is a key material in the construction of pipes and window frames. Polystyrene (PS) is popular for its lightweight nature, often used in packaging and disposable cups.

Comprising nearly one-third of global plastic production, Polyethylene (PE) is the most widely used plastic, known for its versatility and durability. You’ll find PE in everyday items like plastic bags, bottles, and toys. It’s used in both high-density (HDPE) and low-density (LDPE) forms, each serving different purposes.

HDPE is strong and resistant to impact, making it ideal for products like milk jugs, detergent bottles, and piping. On the other hand, LDPE is more flexible and often used in plastic films, grocery bags, and squeeze bottles. PE’s chemical resistance and low moisture absorption make it perfect for packaging food and protecting it from contamination.

One of the reasons PE is so popular is its ease of manufacturing. It can be molded into nearly any shape, which makes it an excellent choice for a wide range of applications. Additionally, PE is lightweight, reducing transportation costs and making it easier to handle.

Despite its many benefits, it’s important to note that PE can contribute to environmental pollution if not disposed of properly. Recycling and responsible use can help mitigate these issues, ensuring PE continues to be a useful and sustainable material.

Polypropylene (PP) stands out for its exceptional versatility and durability, making it a go-to material for a wide range of applications. You’ll often find PP in packaging, automotive parts, textiles, and even medical devices. Its resistance to fatigue means it can be bent repeatedly without breaking, which is why it’s used in living hinges, like the ones on flip-top bottles.

PP is also resistant to many chemical solvents, bases, and acids, making it ideal for containers and lab equipment. Its lightweight nature and ability to withstand high temperatures without melting further add to its appeal. From food storage containers to car bumpers, PP’s adaptability is evident everywhere.

Unlike some other plastics, PP doesn’t absorb water, so it won’t weaken when exposed to moisture. Its insulating properties make it useful in electrical components, too. Another advantage is that PP is easily recyclable, which helps reduce waste and supports environmental sustainability.

Next time you open a yogurt container or use a reusable shopping bag, remember that PP’s durability and versatility are what make these everyday items so reliable. It’s a material that truly proves its worth across different industries and products.

When it comes to construction materials, Polyvinyl Chloride (PVC) is a staple due to its durability and versatility. You’ll often find PVC in pipes, window frames, and flooring. It’s a popular choice because it’s resistant to weather, chemicals, and corrosion. This makes it ideal for both indoor and outdoor applications.

You might notice PVC pipes in plumbing systems. They’re lightweight, easy to install, and don’t rust over time. This helps keep your water clean and safe. PVC is also used in electrical wiring insulation, which protects wires and reduces the risk of electrical fires.

In addition to construction, you’ll see PVC in everyday products like credit cards, toys, and even clothing. It’s easy to shape and mold, allowing manufacturers to create a wide range of items. Plus, PVC can be recycled, which helps reduce waste.

Another benefit of PVC is its cost-effectiveness. It’s cheaper than many other materials, making it a budget-friendly option for many projects. So, whether you’re building a house or just fixing a leaky pipe, PVC is a reliable and practical choice you can count on.

Polystyrene (PS) is a versatile plastic known for being both lightweight and strong, making it ideal for a variety of applications. You’ve probably encountered PS in everyday items like disposable coffee cups, plastic food containers, and even in packaging materials. Its lightness makes it perfect for products that need to be easy to carry, while its strength guarantees durability.

One common form of PS is expanded polystyrene foam, often called Styrofoam. This material is excellent for insulating buildings, keeping heat in during winter and out during summer. It’s also used in protective packaging to safeguard fragile items during shipping. PS is easily molded, so manufacturers can create precise and custom shapes.

PS is also used in more durable products like CD and DVD cases. These cases need to be sturdy to protect the discs inside, and PS does the job well. It’s also found in toys, where its strength and light weight make it safe and easy for kids to handle.

Despite its many uses, remember that PS isn’t biodegradable and can be challenging to recycle. It’s important to dispose of it properly and look for recycling options in your community.

Also Read: Plastic Bag Recycling: Easy Steps for a Clean Planet

Now let’s look at some advanced types of plastic and their unique benefits. Polyethylene Terephthalate, or PET, is widely used in packaging and textiles due to its strength and recyclability.

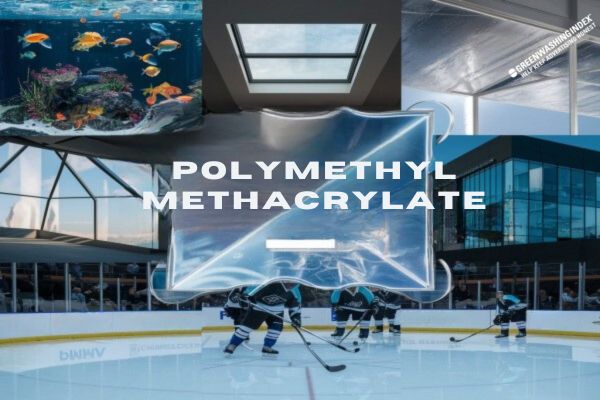

Acrylonitrile Butadiene Styrene (ABS) is popular in 3D printing and consumer electronics for its durability. Polymethyl Methacrylate (PMMA), also known as Acrylic, is valued for its clarity and ability to replace glass.

Among the most common and versatile plastics, Polyethylene Terephthalate (PET or PETE) stands out for its widespread use in beverage bottles, food containers, and synthetic fibers.

You’ve probably encountered PET in everyday items like soda bottles, peanut butter jars, and even in the fabric of your favorite t-shirt. It’s popular because it’s lightweight, strong, and resistant to impact. This plastic also has excellent barrier properties, which means it keeps your food and drinks fresher for longer by protecting them from oxygen and moisture.

One of PET’s great advantages is its recyclability. When you recycle PET bottles, they can be turned into new bottles, clothing, carpets, and even construction materials. This helps reduce waste and conserves resources. PET is also safe for food and drink use, as it doesn’t react with the contents, ensuring the taste and quality remain unchanged.

In addition to being practical, PET is cost-effective to produce and easily moldable, making it a favorite in manufacturing. Thanks to these attributes, PET continues to be a top choice for many products you use daily, proving its importance in the world of plastics.

In various advanced applications, Acrylonitrile Butadiene Styrene (ABS) is renowned for its exceptional strength and durability. You’ll find ABS used in a wide range of products, from LEGO bricks to automotive parts. Its toughness makes it perfect for items that need to withstand impact without breaking easily. This plastic also resists heat and chemicals, making it a reliable choice for many manufacturing processes.

ABS is also lightweight, which makes it ideal for products that need to be strong yet easy to handle. You might notice it in electronic housings, like the casing around your computer or TV. Its ability to be easily molded into different shapes allows manufacturers to create intricate designs without sacrificing durability.

If you’ve ever used a 3D printer, you’ve likely encountered ABS filament. It’s one of the most popular materials for 3D printing because it’s easy to work with and produces sturdy, long-lasting items. The plastic’s smooth surface finish makes it a favorite for creating prototypes and models.

Polymethyl Methacrylate (PMMA), often known as acrylic, is celebrated for its exceptional clarity and shatter-resistant properties, making it a popular alternative to glass in various applications. You’ll find PMMA in products like aquariums, skylights, and even the barriers at hockey rinks. Its lightweight nature and ability to be molded into various shapes make it incredibly versatile.

Acrylic isn’t only durable but also resistant to UV light, which means it won’t yellow or become brittle over time. This makes it ideal for outdoor signage and windows. Additionally, it’s easy to fabricate; you can cut, drill, and bend it without much hassle. This flexibility allows for creative designs and practical uses in both industrial and household settings.

When it comes to maintenance, acrylic is easy to clean with just soap and water. However, you should avoid abrasive cleaners to prevent scratching. It’s also worth noting that while acrylic is shatter-resistant, it’s not completely indestructible, so handle it with care to avoid cracks or breaks.

The environmental impact of different types of plastics is a pressing issue that affects ecosystems, wildlife, and human health. Plastics are pervasive in our daily lives, yet their durability and resistance to decomposition lead to significant pollution problems.

The specific impacts associated with various plastics can help inform better practices for usage, disposal, and recycling. Below is an overview of the environmental consequences linked to plastic pollution.

The various types of plastics and their potential health impacts is crucial for making informed choices. While plastics are widely used in everyday products, some types are more harmful than others due to the toxic chemicals they can leach into the environment and human bodies.

Here’s a breakdown of the most harmful plastics, highlighting their uses and associated health risks.

Awareness of these plastics can help consumers make safer choices and reduce exposure to harmful chemicals.

Despite the environmental damage caused by certain plastics, recycling programs for various types of plastics offer a pathway to mitigate some of these impacts. These programs aim to reduce waste, conserve resources, and lessen the burden on landfills.

You can help by understanding which plastics can be recycled and how to participate in these programs effectively.

Also Read: Single-Use Batteries Recycling Guide: Step-by-Step

When selecting the right type of plastic for your needs, you’ll want to take into account factors like durability, cost, and recyclability. Think about how long you’ll need the plastic to last and whether it needs to withstand high temperatures or heavy use. Also, factor in the environmental impact and ease of recycling each type to make a responsible choice.

Selecting the right type of plastic for your needs involves considering factors like durability, flexibility, and environmental impact. Each type of plastic offers unique properties that make it suitable for different applications. To make the best choice, you should understand these properties and how they align with your specific requirements.

Firstly, think about durability. If you need a plastic that can withstand rough use, opt for a type known for its strength, like Polycarbonate (PC). For applications requiring flexibility, consider Polyethylene (PE) or Polyvinyl Chloride (PVC), which are both known for their pliability.

| Plastic Type | Key Property |

|---|---|

| PET | Recyclable, durable |

| HDPE | Strong, chemical-resistant |

| PVC | Flexible, versatile |

| PC | High impact resistance |

Next, consider environmental impact. Some plastics are easier to recycle than others, reducing their overall footprint. For instance, Polyethylene Terephthalate (PET) is widely recycled, making it a better choice for eco-friendly applications.

Also Read: Repairable Shoes: Step into Sustainable and Lasting Style

What will the future hold for plastics as we seek more sustainable and innovative solutions? As we move forward, the focus will be on reducing the environmental impact of plastics and finding new ways to recycle and reuse them.

Here are some key trends you can expect to see in the future:

The variety of kinds of plastic plays a significant role in modern life, impacting everything from packaging to construction. Each type, including polyethylene, polypropylene, and polystyrene, offers unique properties that cater to specific applications. Understanding these differences is essential for making informed choices about recycling and sustainability.

As the world moves towards greener alternatives, awareness of the various kinds of plastic can guide consumers and industries alike in reducing environmental impact and promoting responsible use. This knowledge fosters a more sustainable future for our planet.