Everyone loves a great pair of jeans; they’re a wardrobe essential. However, despite denim’s widespread popularity, your beloved jeans might have some hidden drawbacks.

Like any garment, denim production involves a complex process. Unfortunately, not all aspects of this process are positive, especially when searching for the ideal pair of jeans.

This blog post delves into the denim manufacturing process and its effects on both society and the habitat. We’ll also showcase a brand dedicated to enhancing denim production,leading the charge towards a more sustainable future for everyone.

All About Denim

The global denim market is worth approximately $65 billion. currently,about 3 billion pairs of jeans are available for purchase.

Denim is a global textile market and wardrobe essential. It’s known for being versatile and durable. Denim originated in France. it then became workwear for American miners.Stars like James Dean and Marlon Brando popularized it, making it a favorite everyday style.

How Denim is Made

Denim is typically made using a cotton twill weave. Approximately 12% of all cotton produced goes into denim production. This twill weave creates a faint diagonal ribbing and is prized for its strength.

Denim creation starts with raw cotton, spun into yarn. This yarn undergoes treatment and dyeing before weaving. Yarn quality, including twist, size, strength, and softness, is crucial. These traits determine how the yarn absorbs dyes. they also impact the final look and feel of the woven denim.

Indigo dye is typically used to create the iconic blue color of denim. Though, indigo struggles to effectively dye cotton. Thus, special chemical treatments and extra steps are necessary to ensure the color adheres properly. Synthetic indigo is now favored over natural indigo. It’s frequently enough applied using a ring-dyeing technique, which leaves the yarn’s core white. This method helps denim achieve its desirable, naturally faded appearance.

Once the yarn is dyed, it’s woven into fabric using a warp and weft technique. The warp consists of long, vertical blue yarns. White weft yarns are then threaded through them on a loom. This woven fabric undergoes finishing processes and treatments.These steps achieve the final,desired appearance.

Denim production involves diverse methods at every stage. Producers choose from various options, resulting in a wide range of denim fabrics, much like the diverse ways we wear them.

Stretch denim is a popular choice. It’s created by adding spandex, elastane, or polyester to the denim. This makes the fabric more pleasant and gives it a better fit.

Denim production involves numerous steps and variations. Each decision made can considerably impact the sustainability of the entire process.

Let’s examine the key environmental issues linked to denim production.

This post is all about the denim industry and the sustainability of MUD Jeans.

The Sustainability Of Denim

Denim’s sustainability might seem obvious. It’s often made from cotton, a natural fiber.

We at Sustainably Kind Living appreciate cotton. However, many other materials are used in denim production.These materials must also be sustainable for the denim to be truly eco-kind.

It’s crucial to examine the entire lifecycle. This includes raw materials, manufacturing, worker well-being, product quality, how it’s used, and what happens at the end of its life.

Raw Material

Cotton quality varies significantly. While frequently enough criticized for high water usage and pesticide application, this isn’t always the case. Compared to other crops, cotton’s impact depends on several factors. These include the growing location, pesticide types and their purpose, and the farming methods employed.

Organic cotton farming offers solutions for responsible management.However,it represents a small fraction of the cotton market (1.4%). Cotton is often chosen for its sustainability. Yet, its actual sustainability varies greatly and is hard to define generally.

Furthermore, many modern denims include stretch, blending cotton with synthetic, fossil-fuel-derived materials. This stretch denim often degrades faster due to its inferior quality and creates challenges for recycling.

Production Processes

This phase often reveals significant sustainability issues in denim production. We, as consumers, are frequently unaware of the numerous elements involved in creating our clothing.

Making jeans often relies on harsh chemicals and damaging processes. these can negatively impact worker health, communities near factories, and the environment. Ultimately, these processes can even affect the people who wear the jeans.

The Toxicity of Denim

The fashion industry frequently enough relies on chemical-heavy manufacturing. Some of these chemicals pose significant risks. Dyes and treatments may contain dangerous substances. These include carcinogens, endocrine disruptors, and heavy metals.

Indigo dye is the preferred method for creating denim’s iconic blue hue. Because indigo pigment doesn’t dissolve in water naturally, special chemicals and processes are needed to bind the color to the yarn.

The dyeing process utilizes several chemicals. These include sodium hydrosulphite, caustic soda, aniline, formaldehyde, hydrogen cyanide, and sodium amide. Sodium amide poses a risk, as it can explode upon contact with air or water. These chemicals are essential for achieving desired colors and effects.

Moreover, dyes are never fully fixed. This means some unfixed dye always ends up in our rivers and oceans. Chemicals themselves aren’t the issue,but their responsible and safe use is crucial. Problems arise when this doesn’t happen.

These chemicals have far-reaching consequences beyond the factory walls and its workers. Toxic chemicals and inadequate wastewater management can devastate communities reliant on fashion production. The documentary RiverBlue vividly illustrates this destruction.

Dhaka, Bangladesh faces severe water pollution from fashion industry waste.Rivers are now lifeless and unusable for the local community due to extreme toxicity.

Likewise, in India, areas near the Ganges River face similar issues. Tannery wastewater contaminates irrigation water. Consequently, these harmful chemicals infiltrate the food supply.

Xintang, China, the world’s denim hub, manufactures a significant portion of China’s and its exported jeans. However, the area has suffered from foul-smelling, blue-dyed rivers caused by denim factories. Untreated wastewater has also lead to heavy metal contamination in the surrounding environment.

Worker Safety

The widespread use of harmful substances throughout the supply chain undeniably endangers workers. This risk starts at cotton farms, where insecticide exposure is a concern. Misleading data often obscures the connection between cotton and pesticides, creating a negative perception.

Cotton farming uses 4.8% of global pesticide sales,according to recent data. This contrasts with the frequently enough-cited figure of 25% for insecticide use. A significant 44% of farmers are affected by pesticide poisoning annually, though this isn’t limited to cotton cultivation.

Research from the Pesticide Action Network in three cotton-growing nations reveals a concerning statistic: 12% of cotton workers experience serious, lasting health problems linked to their jobs. Critically examining pesticide use is vital. These chemicals can cause both immediate and long-term health issues for agricultural laborers.

Denim production poses significant risks due to the chemicals and processes employed in factories and dye houses. The heavy metals present in the dyeing process are highly toxic. They can harm various organs and systems, leading to health problems. These problems range from skin irritations to birth defects and even cancer.

Denim finishing techniques, crucial for achieving desired aesthetics, present significant challenges. Sandblasting, used to create a worn look, generates fine dust. This dust is inhaled by workers, causing lung ailments such as silicosis. Achieving faded, bleached, or acid-washed effects often involves potassium permanganate or hypochlorite. These chemicals release hazardous fumes, leading to respiratory and skin problems.

Working in garment factories can be hazardous and physically demanding. this is especially true if manufacturers and brands fail to prioritize worker safety.

Levi’s, a leading denim brand, is under fire for not joining worker safety initiatives like the Bangladesh and Pakistan Accord.This criticism intensified after four garment workers tragically died at a factory making Levi’s products, succumbing to toxic fume inhalation. It is completely wrong that lives are endangered and lost for the sake of clothing.

denim End of Life

Denim’s impact extends beyond production. It harms both the environment and garment workers throughout its entire lifecycle, even after you’re done wearing it.

Modern denim often includes synthetic fibers for stretch, which complicates recycling. our current recycling infrastructure isn’t equipped to handle these blended fabrics on a large scale.

Moreover, chemical treatments affect a material’s ability to be recycled.Since there are no mandatory reporting or labeling rules for these treatments, separating contaminated parts using current sorting methods is nearly unachievable.

Therefore, most textile “recycling” is actually downcycling.Denim take-back initiatives often shred the fabric for use as insulation.

Moreover, metal parts and labels on jeans pose a recycling challenge. These items require removal before processing in recycling or downcycling facilities. Currently, this deconstruction process isn’t automated. Removing these small metal details demands careful manual work.

Sustainable denim requires recyclability to be a key design consideration.Designers and brands should prioritize mono-materials, non-toxic treatments, and easy disassembly. These factors are crucial for creating a more circular denim lifecycle.

Denim production undeniably has harmful aspects that require change. Sustainable options are available. We need to encourage brands to choose these better options. Making them scalable and affordable is also crucial.

One brand stands out as a true innovator in sustainable denim. They are driving the denim industry forward with eco-conscious production methods.

How MUD Jeans is Making Sustainable Denim

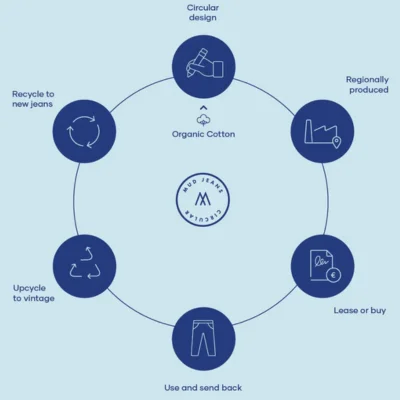

MUD Jeans leads the way in circular denim production. based in the Netherlands,this brand demonstrates how to create eco-friendly jeans. As a certified B-corp, MUD focuses on complete circularity. They use sustainable materials and responsible manufacturing methods.

These companies are pioneering material innovation. They also offer customers a unique chance to rent their jeans for a small monthly payment.

MUD Jeans stands apart for these reasons:

Recycled and Recyclable jeans

MUD is committed to using recycled cotton as a top priority and a leading practice. MUD jeans now blend OCS-certified organic cotton with GRS-certified recycled cotton from post-consumer sources.

Numerous brands claiming to use recycled materials frequently enough utilize pre-consumer recycled content. This includes factory scraps and leftover materials. post-consumer recycled materials, on the other hand, originate from clothing discarded by individuals after they’ve been used.

MUD Jeans utilizes post-consumer recycled cotton, tapping into a frequently overlooked source of fashion waste.Currently, MUD jeans contain 40% post-consumer recycled material, making them leaders in recycled denim. They are actively striving to achieve 100% recycled jeans in the future.

The Road to 100 project partners with a university. It uses both chemical and mechanical recycling methods. They successfully created a 100% recycled sample. Now, they’re using this knowledge on new projects. their goal is to increase recycled content in their denim products, aiming for 100%.

MUD operates a unique denim recycling initiative, creating a truly circular system. They reclaim old jeans and reuse the materials in their new products. Unlike many brands that outsource recycling, MUD integrates recycled denim directly into their own supply chain. They collaborate with recycling partners to transform customer-returned jeans into fresh denim fabric for new MUD jeans.

Moreover, MUD employs entirely stainless steel buttons and rivets. They use printed labels, avoiding leather to keep the denim mono-material. For sustainable stretch, they incorporate recycled elastane or LYCRA® T400® EcoMade. This keeps synthetic material below 4%, ensuring recyclability.

Sustainable & Transparent Processes

Beyond innovative materials, MUD is committed to sustainable practices throughout its supply network. They maintain direct connections with a select group of suppliers. This ensures they have full visibility into the manufacturing process and can guarantee ethical and responsible production methods.

MUD tackles harmful denim production head-on. They’ve stopped using PP spray (potassium permanganate) and use Cradle2Cradle indigo dye. They also prioritize water and energy conservation. Instead of toxic bleaching or stone washing, MUD uses laser, ozone, and “eco-stones” for a stylish, sustainable finish.

MUD excels in transparency and traceability. They openly list their suppliers and provide public access to their Life Cycle Analysis. MUD goes beyond self-advancement. They actively support other businesses and educate professionals and students on sustainable practices.

MUD’s mission extends beyond profit. They are dedicated to transforming the fashion industry. Their goals include eliminating waste and championing a circular buisness model. All this, while crafting remarkable jeans!

MUD Jeans stands out as a truly dedicated sustainable fashion brand. They exemplify ethical practices by treating garment workers fairly, protecting the environment, and providing customers with exceptional value, all while avoiding deceptive marketing tactics.

This post was all about the denim industry and the sustainability of MUD Jeans.

This concludes our in-depth exploration of denim and its environmental footprint. While denim manufacturing requires significant improvements, we’re happy to highlight a brand leading the way in sustainability! If you’re searching for your next eco-friendly denim choice, MUD Jeans is an excellent selection.

Loved this piece on the Denim Industry? Explore these related articles below!